Functional

E/E-Engineering

Tool development and project engineering for E/E-systems Engineering of complex distributed systems for the automotive, railcar, aerospace, marine and communications industry.

Architecture Design & Management

Vehicle E/E-Platforms

Development & analysis of sustainable E/E-system architectures for cars, trucks, trams, trainsets, ships, ...

ECU Systems & Platforms

Development and analysis of adaptable electronic control units (ECUs) with functional safety relevance

ASPICE

FuSa

SAFe

Agile development processes according to all standards and regulations for safety relevant systems

Autonomous Driving

Electric Powertrain

Modelbased engineering of electric powertrains with up to four motors including mechanics, electrics, busses, hardware and software

Steer-by-wire

Brake-by-wire

Drive-by-wire

Modelbased engineering of innovative -by-wire-systems including mechanics, electrics, hardware, software and real time communication

Battery Management Systems

Modelbased engineering of Battery Management Systems (BMS) for Li-Ion / LiFePo cells including mechanics, electrics, hardware and software

Model Based Engineering

Product Reference

Model

Model based engineering of complex products controlled by E/E-systems using a „Digital Twin“ including HW, SW, mechanics, electrics and real time communication

Requirements Model

SYS & SWE

Model based requirements definition and management from system architecture and software architecture down to realtime code and bus communication and gateways

Realtime Communication Model

Model based engineering of sustainable realtime systems regarding the design of ECUs, busses, messages, signals and

gateways. management of signal design & approval

Processes, Methods & Tools

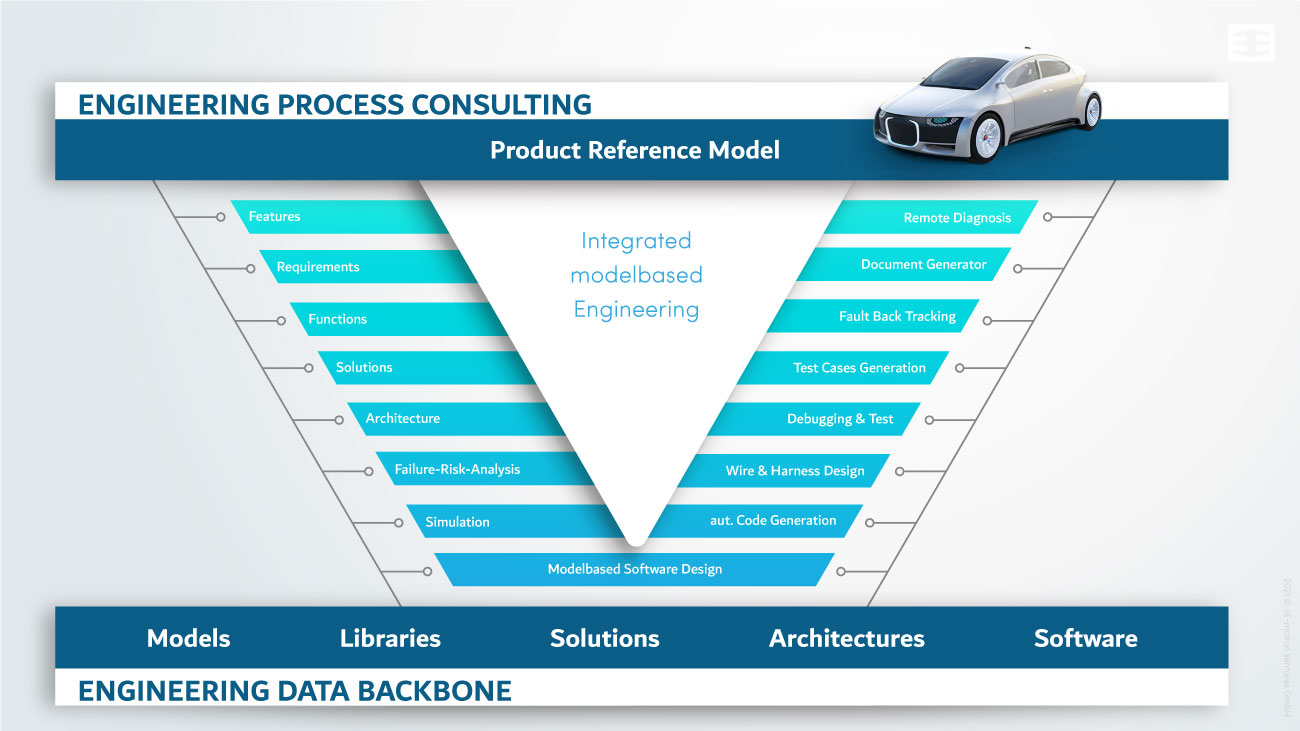

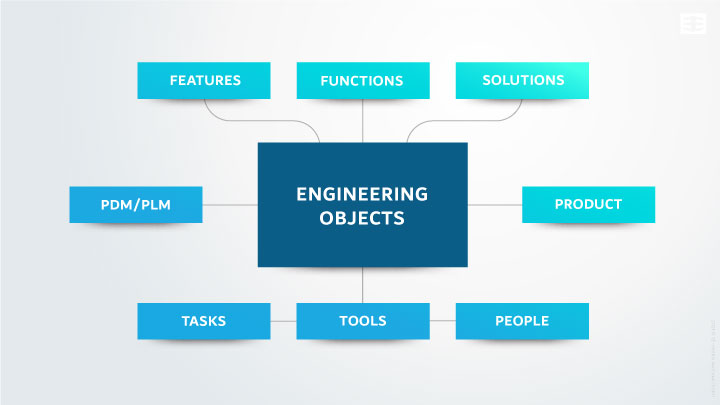

Integrated

Model Based Engineering

Model based engineering of complex products using a Product Reference Model and an Engineering Data Backbone. Integration of all data based on engineering objects.

Virtual Solution Design

The „Virtual Solution Design“ methodology (originally invented for transportation and automation at ABB) reduces time and effort for modelling up to 90%.

ASPICE

FuSa

SAFe

Model based Process Design supports the introduction of agile engineering methods like SAFe in compliance with the rules of ASPICE and functional safety constraints.

Why to act now?

Take the lead.

Mastering mega trends and challenges of E/E-systems engineering, product and process evolution and your way to automation.

Vision of the integrated enterprise: integrated product & process design

World's first fully integrated, modelbased E/E-platform development

The Story

The development team at CTCS (Chery Technical Center Shanghai) consisted of 15 people. Including us. With such a small team we built the E/E-system for the new EXEED TX from scratch in about 2 years.

We supported the development with our E/E-engineering and integration platform ESCAPE and our development method called „Virtual Solution Design“.

All data from previous common development processes such as spreadsheets and text files have been transformed into ESCAPE. From requirements and features down to the ECUs. We developed models and libraries and enabled automatic generation of data, documents and diagrams.

The Task

Support in the development of a new E/E-platform for all future vehicles from CHERY with integrated, modelbased product and process design and the help of our E/E-engineering and integration tool ESCAPE and our method "Virtual Solution Design".

For the first time ever the E/E-system

of a whole new vehicle platform has been

built from scratch

completely integrated and model based

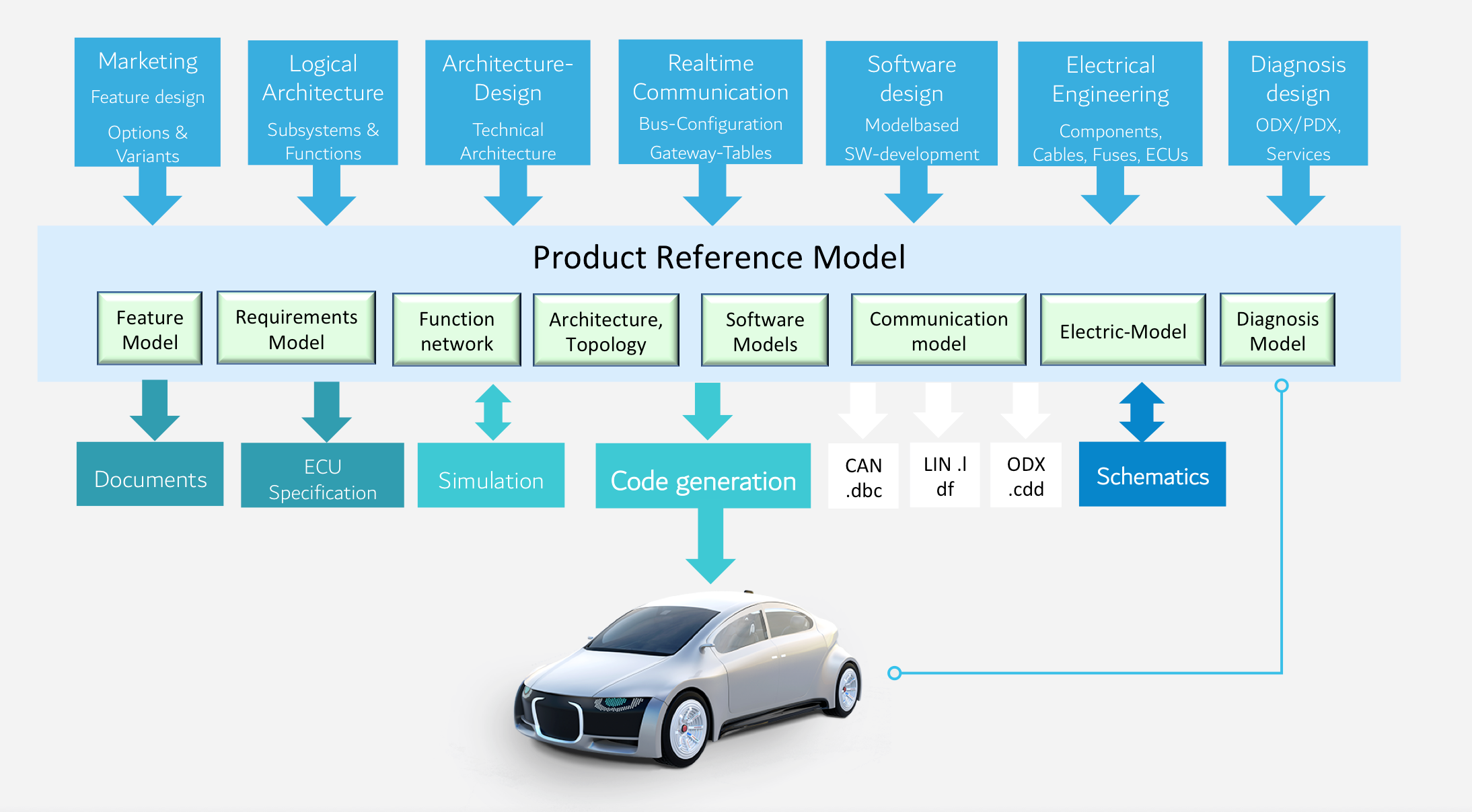

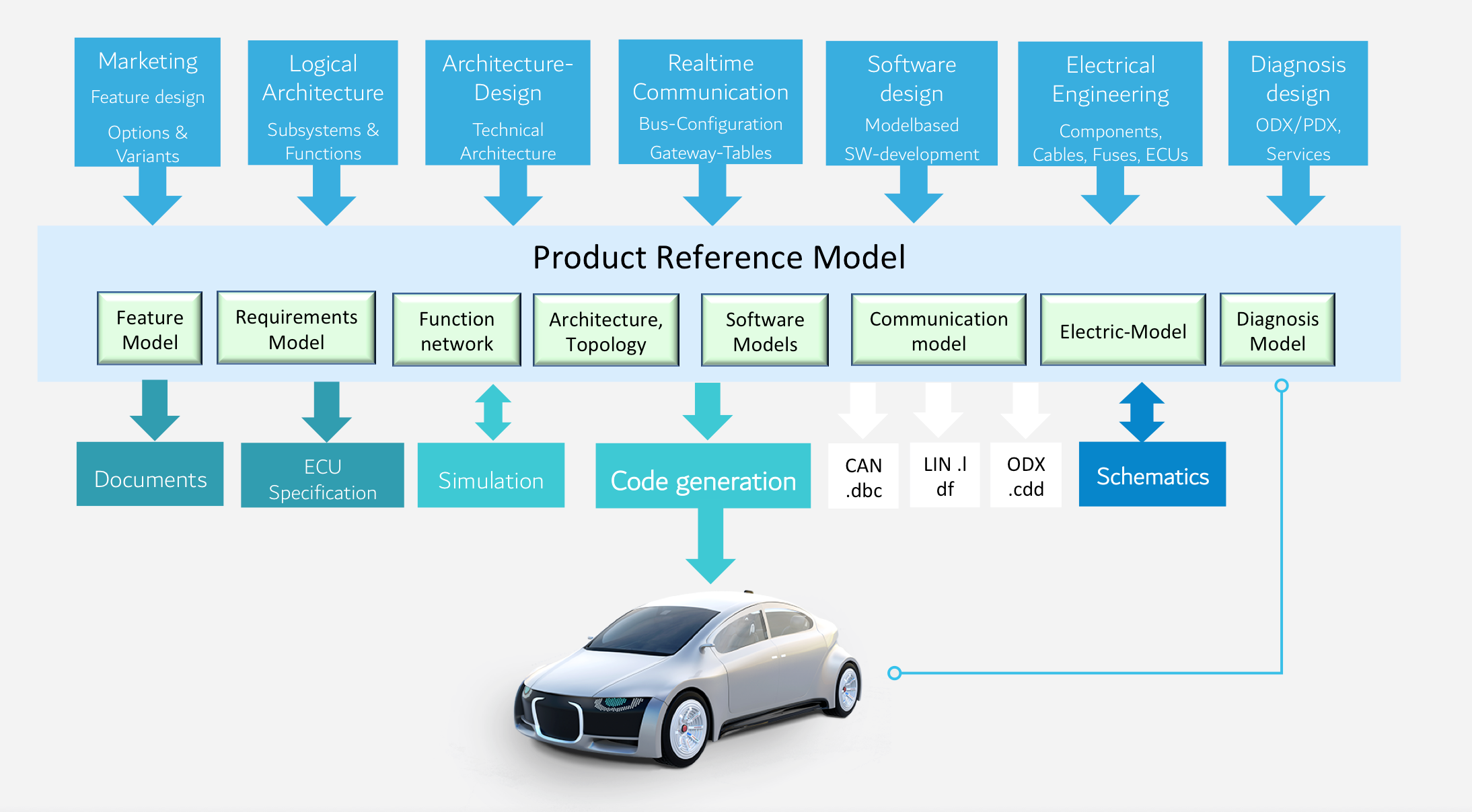

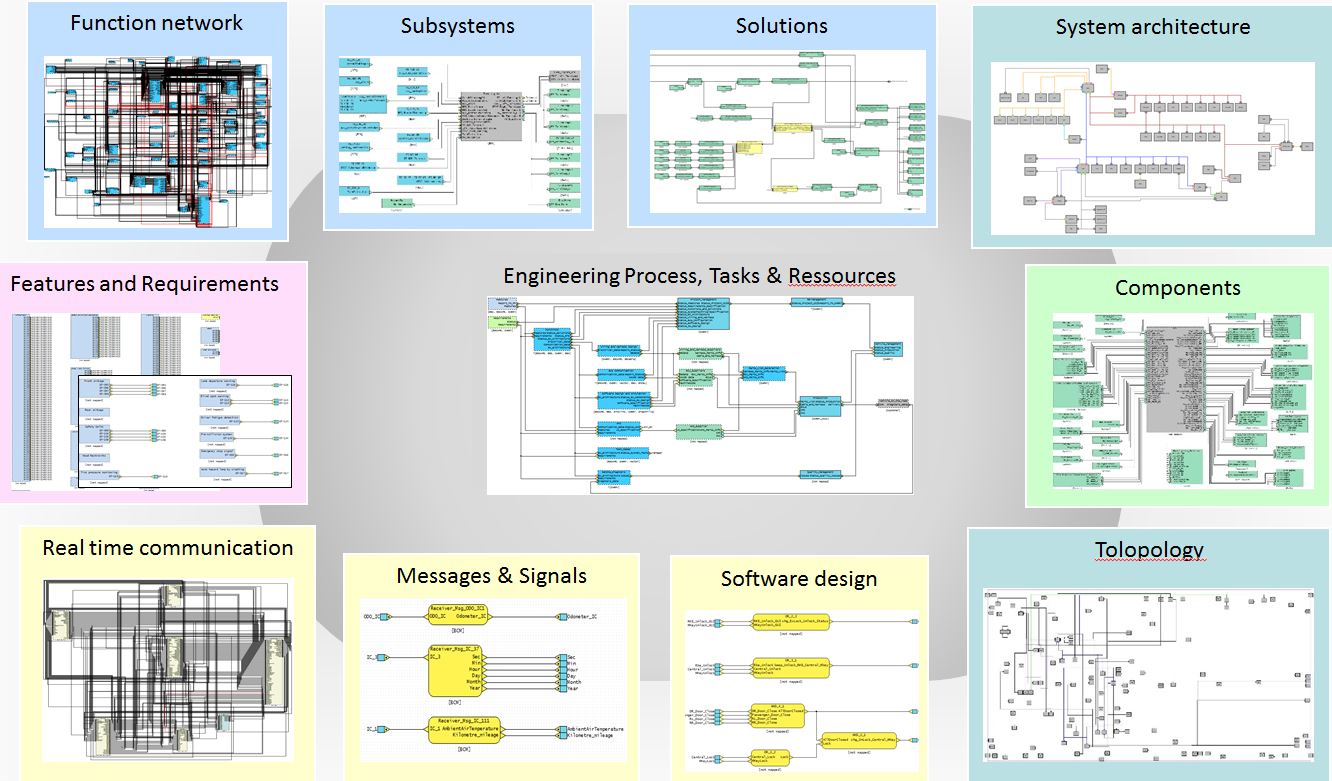

Model based E/E-system architecture design of a new vehicle platform from feature design down to production data

Integration of model based engineering and task automation with the traditional document based process and tools

Redefinition of “State of the art” for integrated model based E/E-engineering

Develop Fast ANd Have Fun.

Integrated Modelbased Engineering

From Feature Design to Serial Code

Discover the power of our integration and development platform ESCAPE.

The Complexity Trap.

ESCAPE it.

OEMs currently face the biggest change in the automotive history since the introduction of the Motronic in 1979.

From a single Combustion Engine Control Unit in BMWs 732 to an always connected electric car, developed function oriented instead of component bound, software driven with frequent over-the-air-updates and the vision of full self driving.

These changes open the door for new business models and opportunities, but they also force the OEMs to change the way they develop the system architectures and components needed to enable the cars to be adaptable, but still safe.

Thus the constant evolution of engineering is beyond question.

But the transformation to a fully digital, model based engineering must be accompanied by the transformation of its counter part on the enterprise side – the integrated enterprise.

ESCAPE THE COMPLEXITY TRAP

Get into control of change with a reference model that covers both the product as well as the process.

5 STEP PROCESS to

Integrated Modelbased Engineering

1

Integrated Process Design

Transform your process without risks. Meet todays challenges, make it competitive and equipped for the future.

We support your transformation with the most innovative and successful methodology "Virtual Solution Design" and the tools you need for authoring and integration.

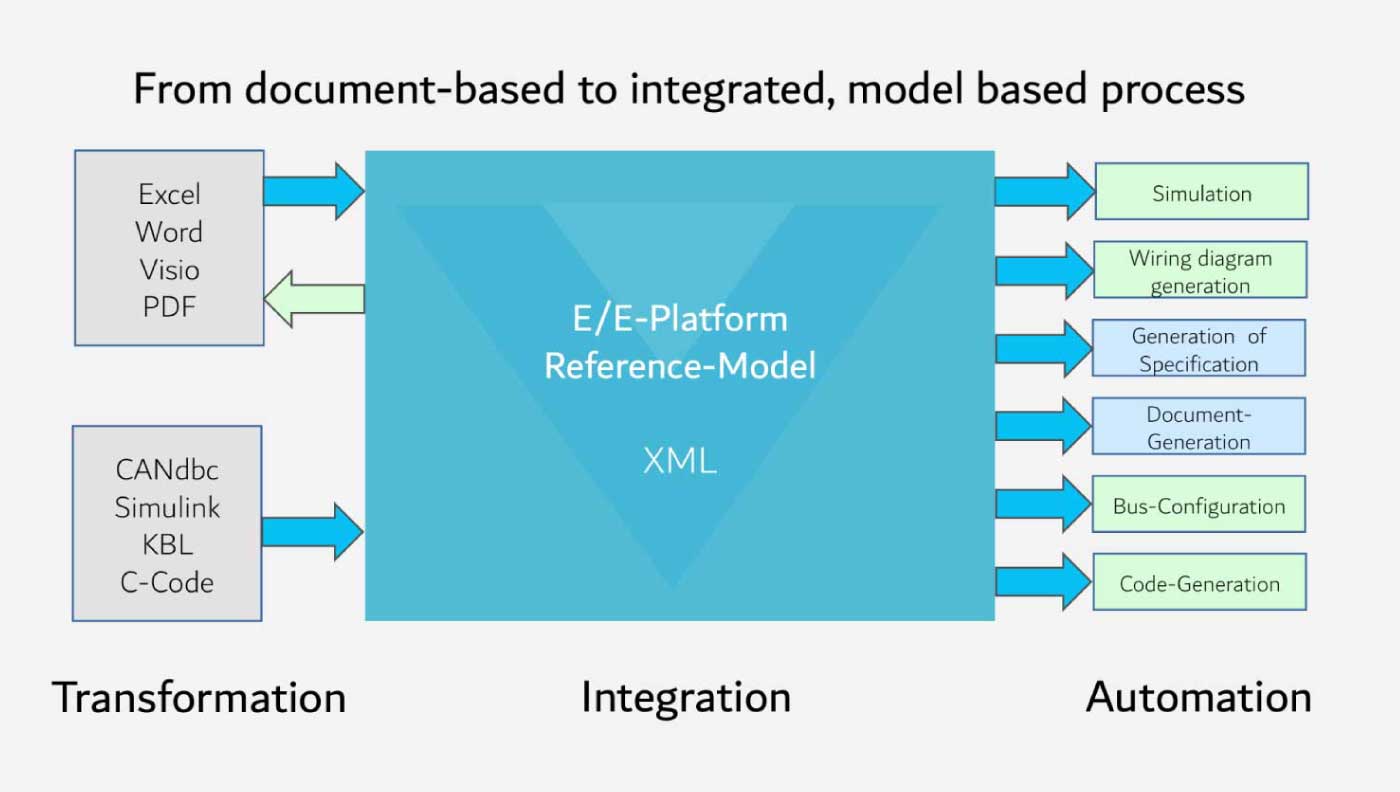

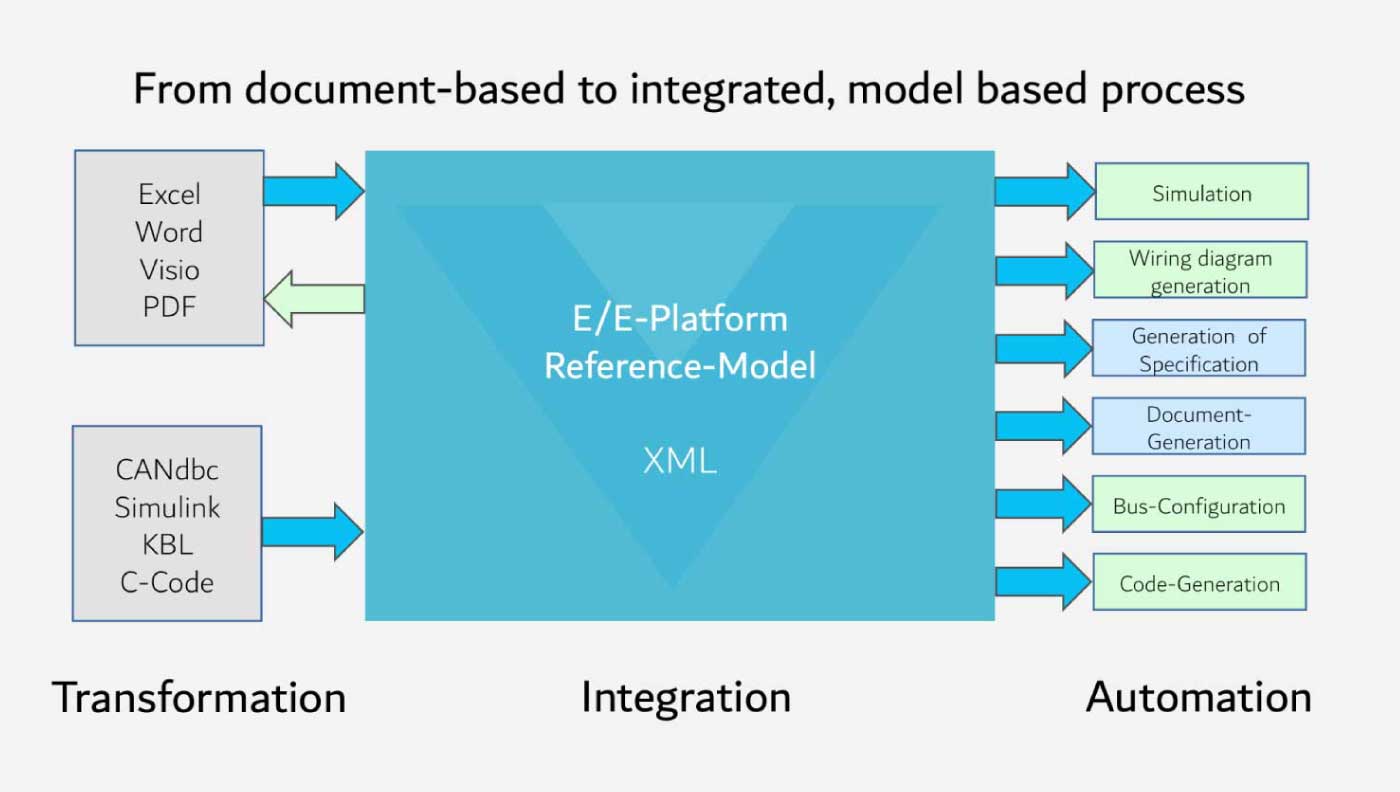

Transformation

We know how to build the bridge between traditional engineering and model based, integrated design. Benefit from this experience in methods and tools.

Integration

The integration of all the data and tools is the key to reduction of costs, effort, time and risk in E/E-Engineering. We provide the platform needed for integration.

Automation

30 years of vehicle E/E-systems development teached us how to automize engineering tasks. We provide the tools needed to free your engineers for innovation.

Implementation

Your success is our mission. Therefore our experts support the implementation of the process as well as the introduction in first projects at your site.

2

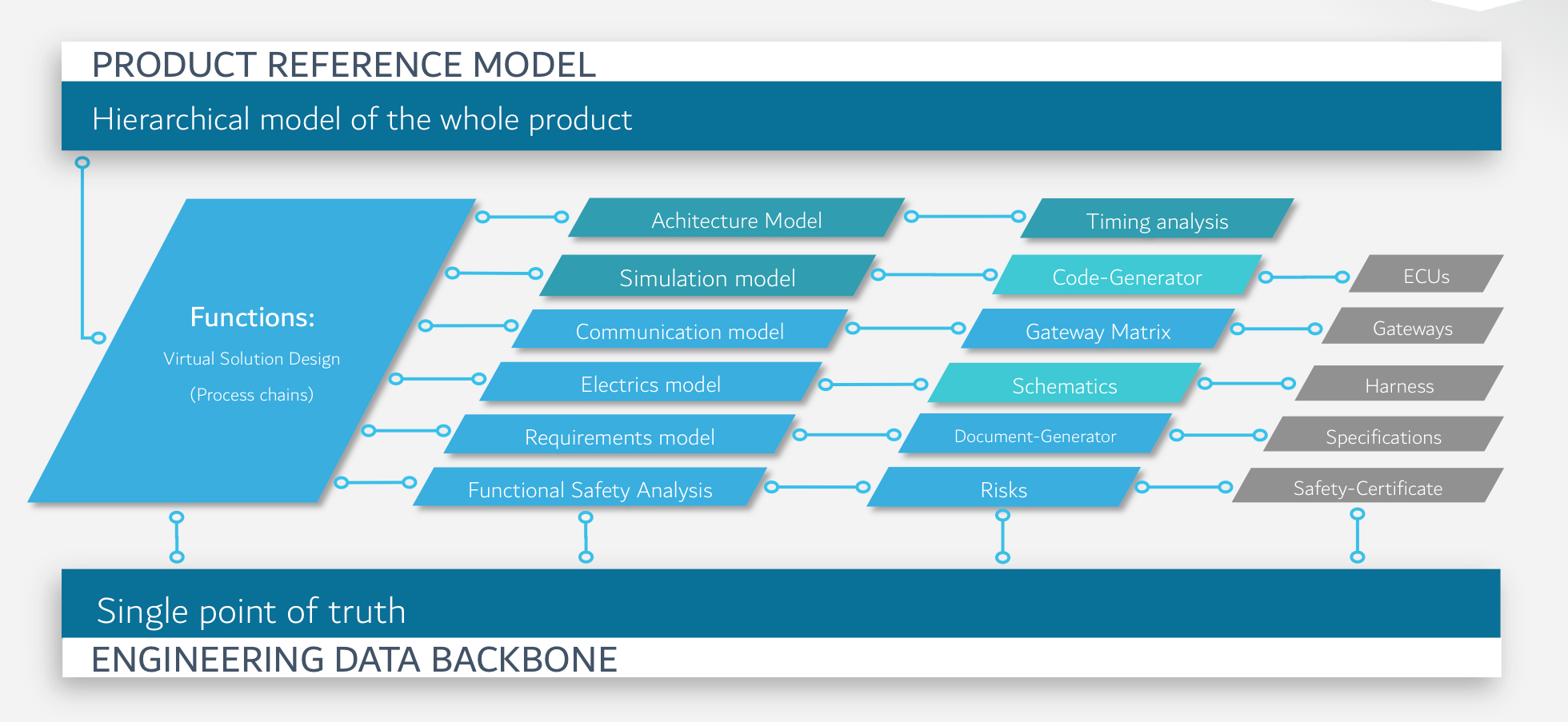

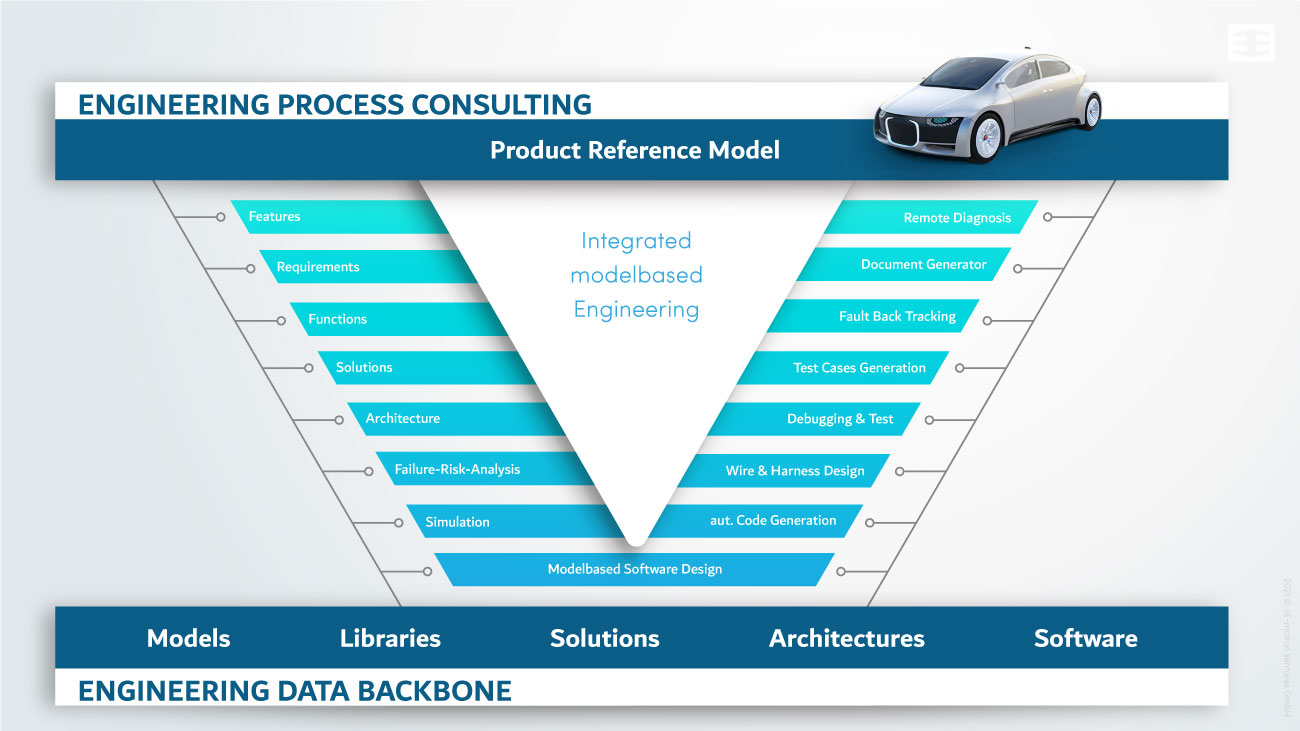

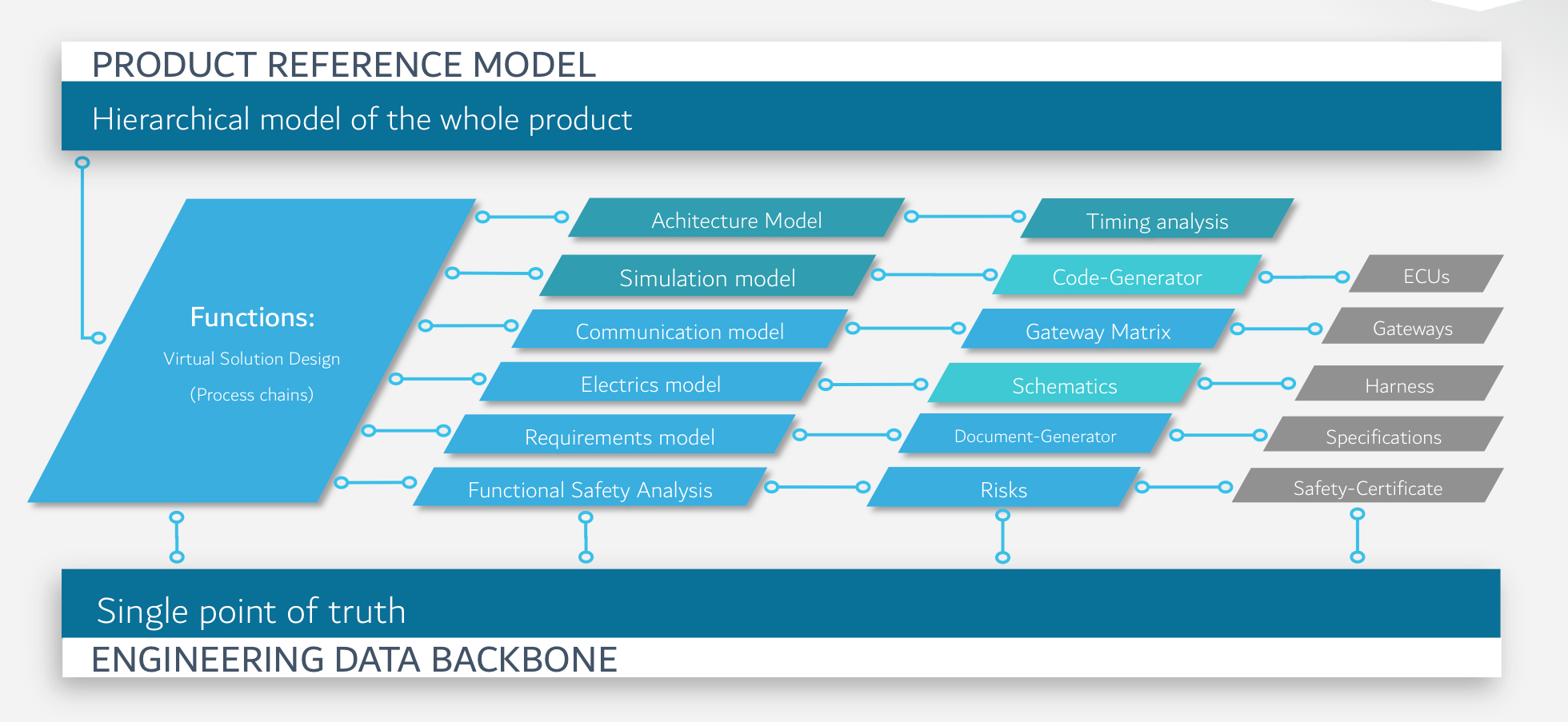

Product Reference Model

Hierarchical, function oriented vehicle model

Design & Development

Model-based specification, analysis, simulation and implementation based on functional models

Verification & Validation

Automatic generation of control unit code, electrical circuit diagrams, real-time communication and documentation; online access to data on the delivered product

Digitalize Spreadsheets & Co

Transform your manually handled spreadsheets and text documents in visually navigatable function models in ESCAPE. From feature to diagnosis model – up-to-date and downloadable at any time.

3

Engineering Data Backbone. The Single-Point-Of-Truth.

Most significant today: Own your data. Get the knowledge back in-house and everybody working on the same page – your page – your platform.

For a long time, knowledge has migrated to the suppliers. OEMs no longer own the complete knowledge and code. But for quite some time now, the trend is reversing. It’s getting more and more crucial to know and own all data for mastering requirements resulting from todays megatrends.

Collect Knowledge

Get everybody working on the same page, on one plattform and store solutions in one secure spot – your Engineering Data Backbone, the „Single-point-of-truth“.

Share Knowledge

Develop product reference models with our E/E-engineering tool ESCAPE and reuse engineering objects, functions or solutions across all products and variants.

Collaborate

With all your data stored in one secure spot, content and role specific accessible by all your departments, and real-time data synchronisation collaboration in this complex environment is made easy.

Save Time & Money

Engineering objects only exist once. All tools work on the same objects, the same database. Effort, sources of error and redundancies are minimized or completely eliminated.

4

Process Modelling

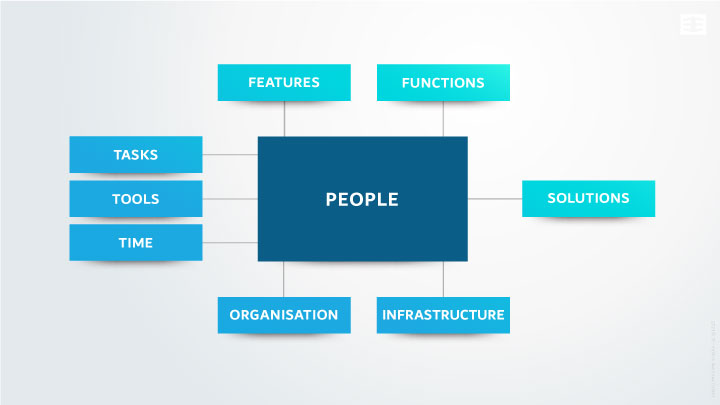

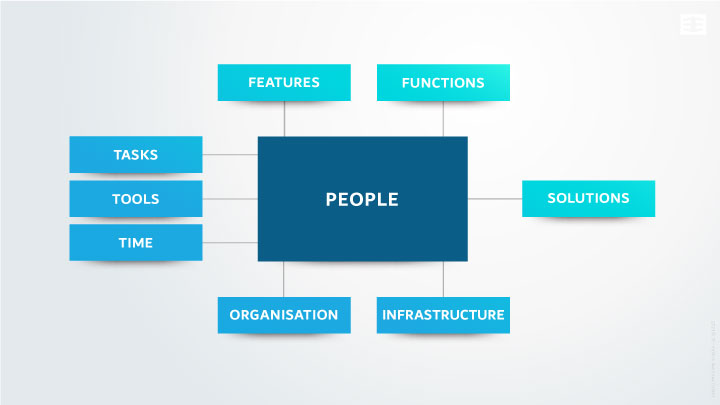

People

It’s all about the people. Designers, controllers, engineers who create your products. Know about what they do (tasks), how they do it (tools) and when they achieve their goals (time).

Product

People create innovative products defining, designing and implementing it according to the features and functions required to excite your customers. Get to know who does what, when and why.

Prerequisites

Innovative product design needs an environment for creative people and an infrastructure that cares about all your data. Control your process and adapt it’s organization always according to the needs.

Progress

Build a model of your digital enterprise and optimize it by analyzing the workload, the interfaces and the supply chains. Process modelling provides the tools for a continuous improvement.

5

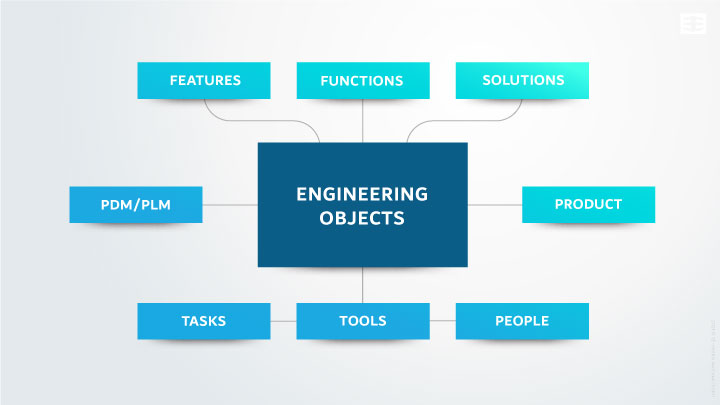

Integration of Process Model & Product Model

Provide

the data and the knowledge about your product based on a fast and safe infrastructure, built on the latest PDM/PLM-solutions from the market and managed by international market leaders.

Proceed

with the optimization of your process by integrating the product design with the process implementation. Analyze the impact of a change on both your product as well as your organization.

Program

your products software using the most sophisticated and highly automized model based tools and technologies. Don’t let the complexity and safety of your code make you worried any longer.

Produce

your products with a seamless flow of model based data from your proven solutions down to the shop floor. Using automized generation of schematics and documents consistency is guaranteed.

ESCAPE V8.2

E/E-Engineering & Integration Platform

3E-motion is specialised in functional integrated modelbased E/E-Engineering, with our impact on the industry stretching back until the 1990‘s.

We own a worldwide unique know-how about CAPE (Computer Aided Plant Engineering), the functional development of complex electronic systems in mobile applications on land, on water and in the air.

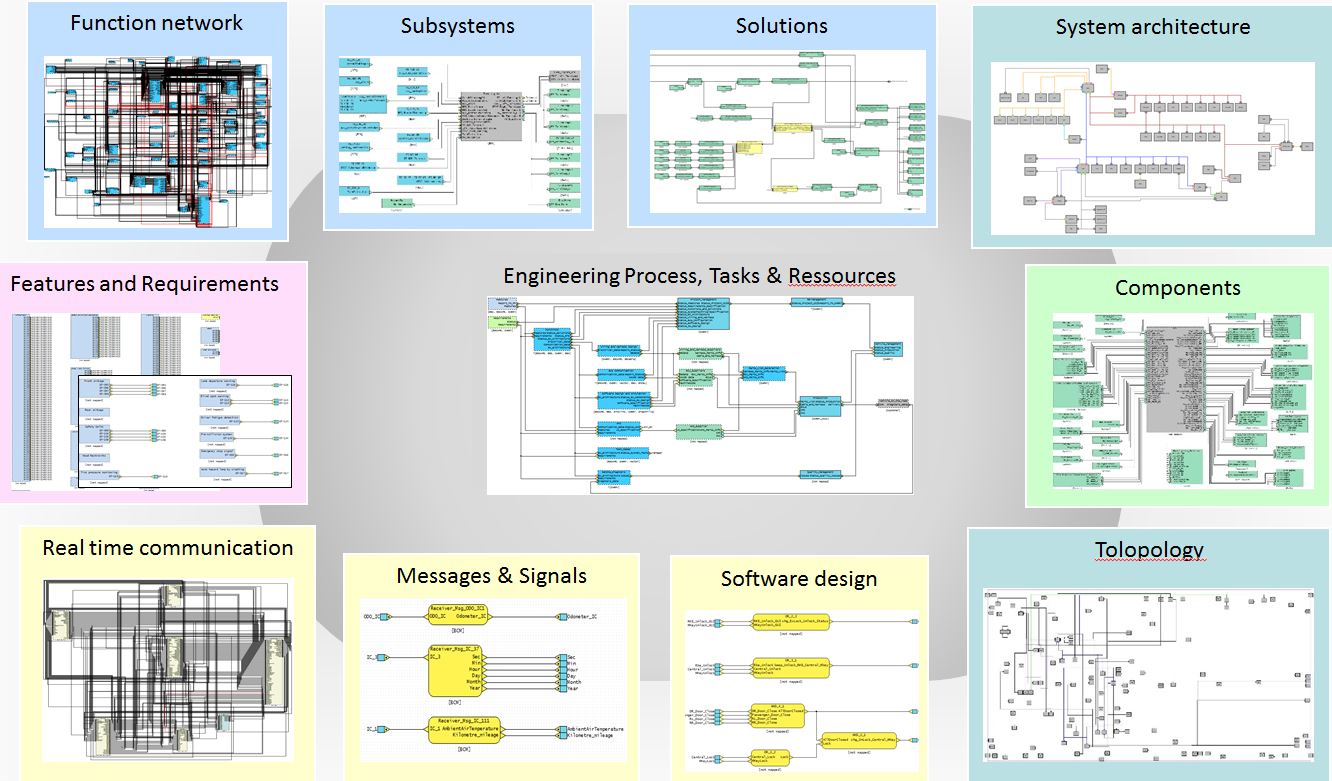

The Virtual Solution Design methodology implemented in ESCAPE enables the model-based mapping of electronically controlled products of the highest complexity, from individual control units to a complete power plant.

Complete Integrated Modelbased Engineering Process

ESCAPE provides integrated engineering throughout the whole process of E/E-engineering from feature design down to serial code.

System Architecture Design

Communication Design

Feature Design

Requirements Management

Failure Effects Analysis

Fault Back Tracking

Integration & Development Platform ESCAPE

Development and implementation tools required in the course of engineering, such as Simulink, EBcable, CANdb, are integrated into the model-based process via an ESCAPE model of the entire vehicle.

This integration allows the completely consistent model-based development from requirements to serial code.

Model Based ECU development

Raptor / Simulink integration

CanDB integration

Communication Network

Simulink Blockset Available As Software Library

Topological View of Car/Components/Bus Signals

Fast Forward to Automation

From document based to integrated modelbased process

We don't just offer a tool, we can guide you through the entire process.

From manually handling countless spreadsheets to a completely integrated product model in ESCAPE. From integration of requirements through the E/E-system architecture to the automatic generation of serial code.

Minimize time and costs now. With ESCAPE.

Transformation

Transform your knowledge and data from spreadsheets and documents into a generic solution model.

Manage your data in one secure spot, your engineering data backbone, the „single-point-of-truth“.

Integration

Take advantage in the integration of the tool islands in your process into a common model platform.

Save time by creating the input for simulation, implementation and production automatically from your product reference model.

Automation

Create simulation models right from every level of your product reference model.

Generate ECU models including OS- and task-configuration and generate production code right out of your ESCAPE model.

Create your wiring diagrams at the push of a button, no worries about inconsistencies between the functional design and the electrics implementation.